IFES manufactures fire alarm panels for its Foam Mobile Fire Suppression systems.

These conform to AS 5062 and are manufactured to be simple to use, and reliable...

These conform to AS 5062 and are manufactured to be simple to use, and reliable...

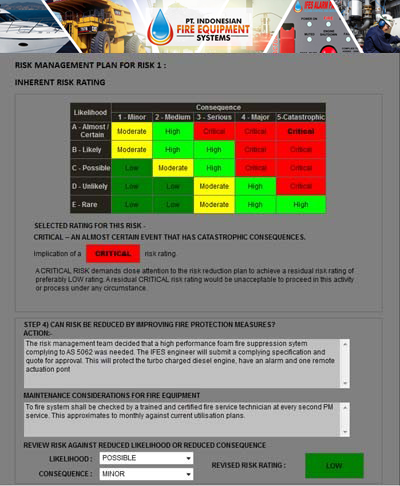

To comply to Australian Standard AS 5062 - 2006, it is mandatory to use a complying risk reduction procedure. The technical manager and commissioner of IFES, Mr Leigh Waldon has been using the process used in IFES for more than 15 years. This has helped major mining companies get real results with less fires with fire suppression systems that are more reliable and more successful at putting out fires.

Leigh’s fire systems have put out many fires for customers over the years. Most fire systems cost less than 1% of the machines purchase price. Even if you have only one fire a year on 50 haul trucks, you have saved a large amount of money. Fire suppression systems save customers money by keeping your expensive equipment protected and still working.

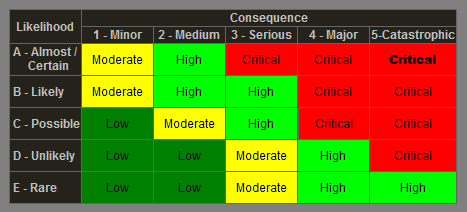

An extract from IFES risk management training "It is not possible to eliminate risk but we can reduce the likelihood and we can reduce the consequence and make the risk acceptable"

The consequence is rated between CATASTROPHIC an MINOR. The WRAC chart is then used to categorise the resulting risk. Then a process which follows the AS 5062 format is used to look at areas that can reduce the risk of fire. This can be better machine design, better training and better safety procedures. Then options are looked at to reduce the consequence of fire. This is where IFES really comes to help. Our fire suppression system is there to respond fast and get that fire out. Experience shows that fire suppression systems that perform well can minimise damage so the machine can be quickly repaired and put back to service

IFES uses the world renown WRAC process. This stands for Workplace Risk Assessment and Control. It is very popular in industry because because it is simple to follow and easy to teach. It is based on the relevant team of people, collaborating together to firstly establish the inherent risk rating. This is done by considering for each possible fire risk, the likelihood of it happening between ALMOST CERTAIN and RARE.

FOAM MOBILE FIRE SUPPRESSION SYSTEMS

Our Products

Ruko Haryono Palace No. 22

Jl. MT Haryono, Balikpapan

Kalimantan Timur, Indonesia 76114

Jl. MT Haryono, Balikpapan

Kalimantan Timur, Indonesia 76114

Phone : +62 542 887 9145

Fax : +62 542 887 9146

e-mail : info@fire-equipmentsystems.com

Fax : +62 542 887 9146

e-mail : info@fire-equipmentsystems.com

Call : +62 542 887 9145

IFES has developed leading design rules together with matching software. IFES has used its fire simulator to develop much more accurate hydraulic performance prediction algorithms which are proven in practical test...

RISK REDUCTION